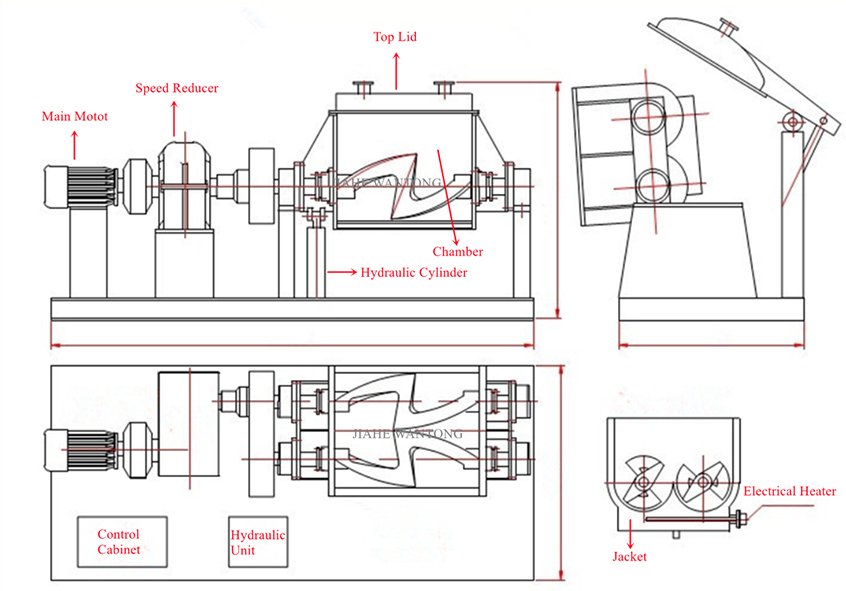

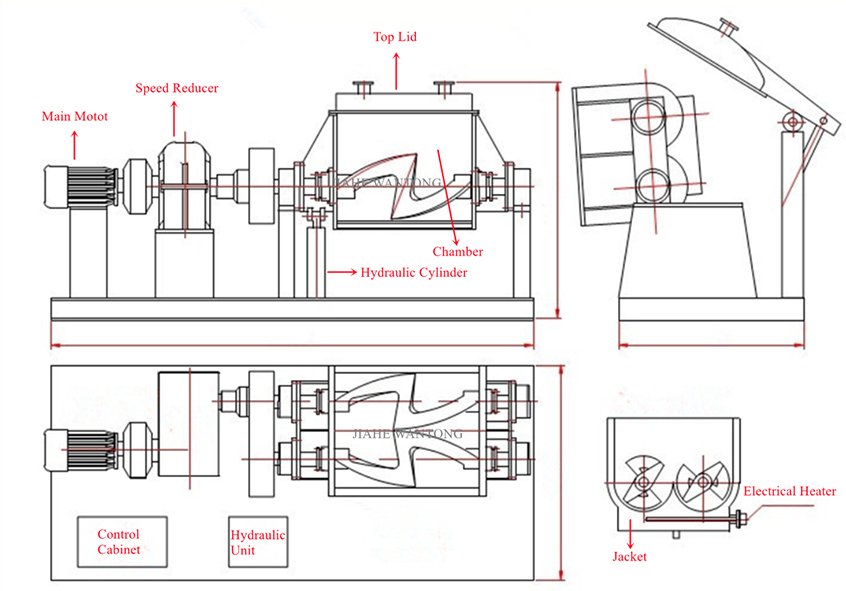

Tilt Discharge

Customizable

◆Capacity from 2L to 5000L

◆Material SS304,SS316,SS316L,carbon steel or other special material

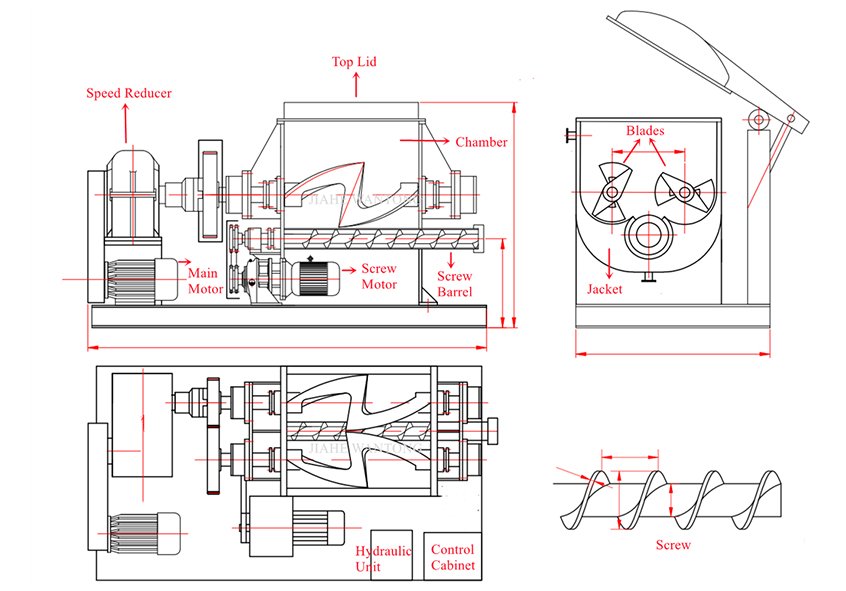

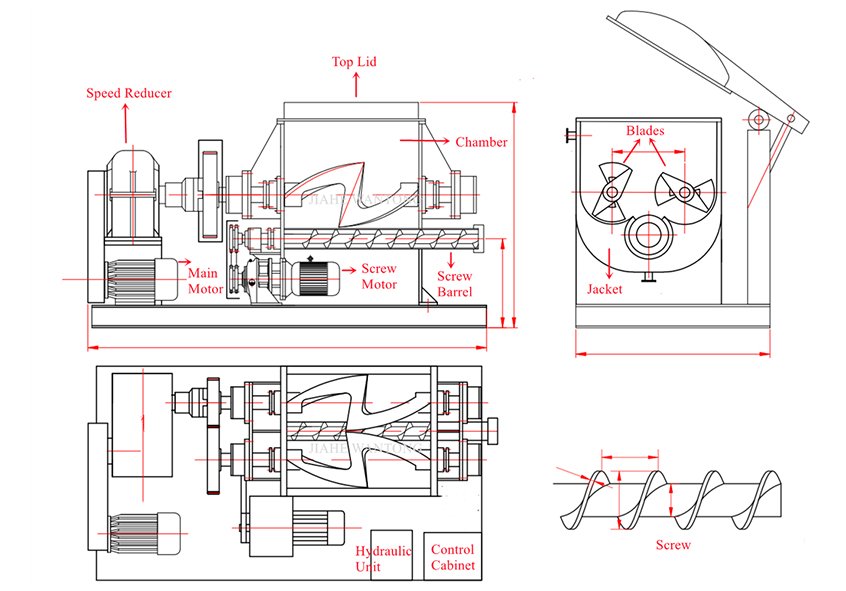

◆Screw extruder,tilt or bottom valve can be choosed for discharging

◆Heating,cooling,vacuum,pressure,explosion proof can be as required

◆Voltage 120V,220V,230V,380V,400V,415V,440V,600V or others

Screw Extruder

Safety

◆CE certification can be provided

◆All machines are manufactured according to ISO9001

◆Professional engineers provide production design and after-sales service

◆All machines operational test at least two times before delivery

Applications

▪ The Sigma/Z Blade Kneader Mixer According To Function:

Vacuum Type,Pressure Type,Atmospheric Pressure Type,Heating Type,Cooling Type

▪ The Heating Methods Can Be:

Ordinary Electric Heating,Zero Distance Heating,Jacket Steam Heating,Jacket Oil Heating, Jacket Water Heating

▪ There Are Three Discharge Methods For Sigma/Z Blade Kneader Mixer:

Tilt Cylinder Discharge, Screw Extruding Discharge, Bottom Valve Discharge

▪ The sigma/z blade kneader mixer are generally used for kneading, mixing, crushing, dispersing, and reaggregating various chemical products of high viscosity slurries or elastoplastic material.

▪ The sigma/z blade kneader mixer are widely used for high-density sealants, neutral glass glue, acidic glass glue, hot melt,silicone rubber, butyl rubber, rubber, pulp, cellulose, batteries, inks, pigments, dyes, pharmaceuticals, resins, plastics, cosmetics, carbon paste, clay, plasticine, BMC and other chemical products,it can also be used for dough, syrup, chewing gum, bubble gum, chocolate and other food products.

Model | Motor Power (KW) | Heating Way | Steam Pressure (MPA) | Vacuum Degree (MPA) | Pressure (MPA) | Shape Size (M) | Weight (KG) |

2L | 1.1-2.2 | Electrical,Cycle Steam/ Hot Oil/Hot Water In Jacket | Usually 0.3(Can Add As Requirement) | -0.098(Vacuum Type) | 0.45(Pressure Type) | 1.1*0.4*0.5 | 150 |

5L | 1.1-2.2 | 1.3*0.5*0.6 | 200 |

10L | 1.1-2.2 | 1.4*0.5*0.7 | 300 |

50L | 2.2-7.5 | 1.5*0.7*1.0 | 600 |

100L | 4-11 | 1.8*0.6*1.3 | 1000 |

200L | 5.5-15 | 2.0*1.2*1.5 | 1800 |

300L | 5.5-22 | 2.5*1.2*1.6 | 2200 |

500L | 11-22 | 2.8*1.4*1.6 | 3000 |

1000L | 15-37 | 3.0*1.5*1.8 | 4500 |

1500L | 18.5-45 | 3.3*1.9*1.9 | 5500 |

2000L | 37-75 | 3.5*2.2*2.2 | 6800 |

3000L | 45-110 | 4.5*2.2*2.2 | 9500 |

Factory Information

FAQ

Q:Why choose us?

A:1.We have rich experience for chemical and food machines more than 10years.

2.We have professional team to provide pre-sales and after-sales service for you.

3.Our quality praised by our customers and we provide very competitive price for you.

4.We will provide lifetime maintenance for the machine.

Q:How about delivery time?

A:The delivery time is about 15-30days after confirm cooperation,details will depend on products.

Q:Is the customization available?

A: Yes,machines can be customized based on clients’ request.

Q:How about payment terms?

A:T/T,LC

If any more information you want,please send us a enquire below,we will back to you in 12hours!